How to Schedule Staff Based on Store Traffic

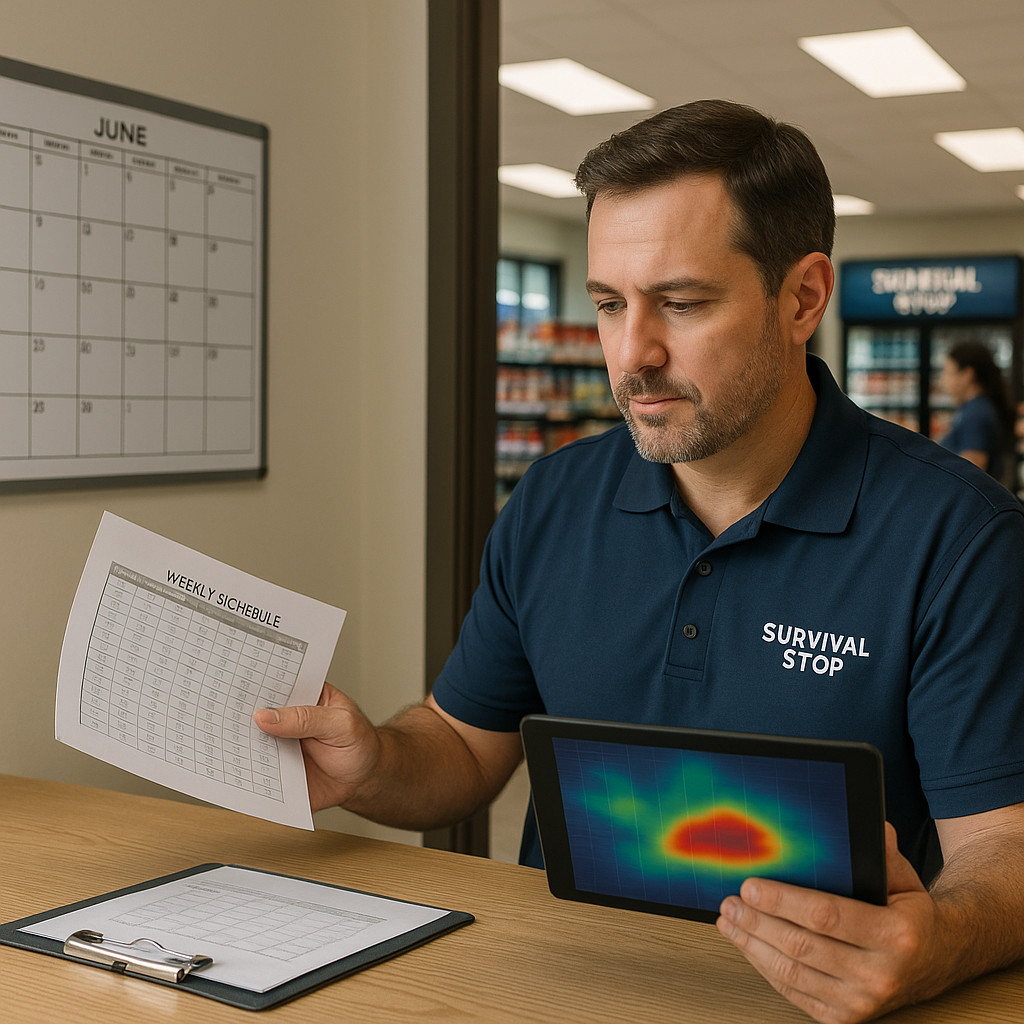

Stop playing scheduling roulette based on personal preferences. Smart scheduling matches staff to actual store traffic patterns through data tracking, color-coded peak periods, and strategic placement of your strongest employees during busy times.

For Assistant Managers Who Want to Stop Guessing and Start Scheduling Smarter

Every convenience store has its own rhythm — early morning coffee runs, midday snack grabs, and late-night beer pickups. But if you’re still writing the schedule based on who “usually works Mondays” or who “likes mornings,” you’re playing scheduling roulette.

Let’s fix that.

📉 “We Were Always Either Scrambling or Standing Around”

A few years back, I took over a struggling store near a busy freeway. Sales were solid, but morale was in the tank. On Mondays at 8 a.m., lines would snake around the register while two stressed-out employees ran the store. But by 2 p.m., five people would be on the clock… mostly checking their phones.

It wasn’t a staffing problem. It was a traffic pattern problem. And once we mapped our foot traffic and started scheduling around it — instead of personal preferences — things turned around fast.

🛠 Step-by-Step: Smarter Scheduling Based on Store Traffic

1. Track Traffic for 2 Weeks Straight

Before you can fix a pattern, you need to see it. Use any combo of:

- Register reports (sales volume by hour)

- Customer counts from your POS

- Manual tally sheets at the door

- Your own observations (yes, grab a notepad)

Group the day into blocks (early morning, lunch, afternoon, evening, late night) and track how many customers you serve per block. Repeat for 14 days.

2. Color-Code Your Peak and Slow Periods

Once you have data, color-code it:

- 🔴 Red = Peak (lines, high pressure)

- 🟡 Yellow = Medium (steady flow)

- 🟢 Green = Slow (routine tasks)

Hang this “heat map” on the back office wall. This helps your whole team understand when the store really needs coverage — and when it doesn’t.

3. Build the Schedule Backward from Peak Hours

Start by placing your strongest, fastest employees in red zones. Then layer in support:

- 1 register runner

- 1 floor/cooler restock

- 1 float (flex role)

In slow periods, reduce headcount to your minimum needed for customer service, cleaning, and safety. Assign tasks like deep cleaning or stock audits during these times.

4. Use Overlap Wisely

Don’t create expensive overlap during slow blocks. Instead:

- Schedule 15–30 minute overlaps before and after peak blocks

- Use overlap to hand off tasks, review notes, and prep the next shift

5. Post It Early — and Stick to It

Employees respect structure. If the schedule is posted on time and tied to real store needs, it becomes easier to enforce. No more “Why can’t I come in at 10 instead of 8?” conversations.

❌ Common Scheduling Myths That Cause Problems

|

Myth |

Why It’s Wrong |

|

“More people = better service” |

Not if they’re standing around doing nothing. |

|

“We always need 3 people on shift” |

Needs vary by time of day. Blanket rules don’t work. |

|

“He’s been here the longest, so he should get first pick” |

Seniority matters, but scheduling is about store needs

first. |

✅ Takeaway: Scheduling Based on Traffic Makes Everything Easier

When you match the schedule to real demand:

- Customers are happier

- Employees feel less overwhelmed

- Labor costs stay in check

- You look like a boss who actually knows what they’re doing

📥 Quick Reference Checklist

✅ Track customer traffic by time block

✅ Mark red, yellow, green traffic zones

✅ Schedule your A-team for peak hours

✅ Minimize overlap in green zones

✅ Post the schedule early and explain the “why”